Rubber and its Compounding

- Post On02.02.2021

- ByNiket Lachake, Pradip Shingote

What is Rubber ?

Natural rubber, also called India rubber or caoutchouc, as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds, plus water. Forms of polyisoprene that are used as natural rubbers are classified as elastomers. Rubber is harvested mainly in the form of the latex from the rubber tree or others. The latex is a sticky, milky colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". The major commercial source of natural rubber latex is the Pará rubber tree (Hevea brasiliensis).

Important Rubber Properties

The unique property of rubber is that it is elastic. When rubber is stretched, the molecular bonds can be extended out. When released, the molecules coil back to their original shape. In its raw state rubber consists of long randomly kinked hydrocarbon chains which can slide past each other. Raw rubber is therefore plastic, weak and permanently deformable. The purpose of vulcanization (also called curing) is to chemically link the rubber chains together by "crosslinks" to form a three-dimensional network.

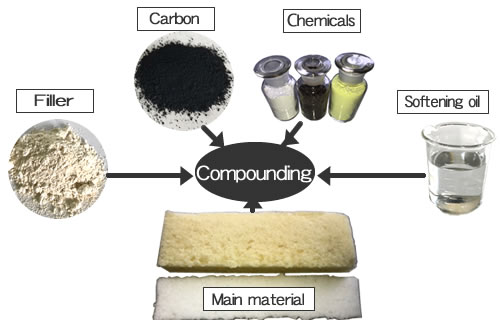

Rubber Compounding

A rubber compound could be a combination of 3 to 15 different ingredients of thousands of different compositions and vendors. A typical rubber formation based on parts per hundred is:

Polymers:

The most important ingredient in a rubber compound, polymers give the bases for chemical, physical and molding properties. An example for a Nitrile (Buna-N) compound is the amount of Acrylonitrile (ACN). The higher the ACN, the more oil resistance. These polymers are then sold with varying ACN content.Filler:

Carbon Black is one of the most common fillers. This gives the rubber compoundphysical strength and its black color. There are various particle sizes and surface activities. Changing the particle size can increase physical properties while also increasing compression set.Antioxidant:

Antioxidants help protect the compound from high temperature while in use and while the compound is being mixed. These ingredients can absorb free radicals that can break the polymers bonds and reduce service life of the compoundAntioxidants:

The most common antiozonant is wax, used to bloom out on the surface after molding to protect the rubber from ozone attack. A common example can be seen when purchasing new tires. The surface of a new tire will have a wax feel or show a slight haze.Cures:

Various oils are used to help incorporate all the dry ingredients used in the rubber compounding. They also help to reduce the viscosity of the overall compound to help with molding. Adding more oil can also lower the hardness of the rubber.Oil (processing aids):

Sulfur is the most common curative for rubber compounds. Rubber polymers are just entangled hydrocarbon chains than won’t hold shape. Back in 1839, Goodyear discovered that rubber chains can be bonded together by heating the rubber with sulfur, called vulcanization.

Rubber Compounding

Natural Rubber:

The raw material to make natural rubber actually does come from trees Produces compounds with high tensile strength, tear strength, tear and abrasion resistance Can be used at lower temperatures, low compression set, and high resilience Not recommended for severe applications with oil and solvent exposure; subject to aging by sun, ozone, and heat. Also not good for applications in contact with concentrated acids or alkalNeoprene(Chloroprene):

Good general purpose rubber with properties close to natural rubber, but is synthetically produced Better resistance to oils and solvents compared to natural rubber but similar low compression set. Can be compounded for flame resistance Good weathering resistance Poorer low temperature performance compared to natural rubber. Not good in applications with concentrated acids or alkalis. Maximum continuous operating temperature is about 275°F.Nitrile(Buna):

Much better oil and solvent resistance compared to either natural rubber or Neoprene. Recommended for most oil field applications. Can be formulated for use at low temperatures. Good compression set and abrasion resistance, but poor weathering resistance. Can be used with concentrated acids and alkalis but there are better alternatives. Maximum continuous operating temperature is about 275°F.HNBR(Hydrogenated Nitrile):

Similar to Nitrile but with improvements in heat and ozone resistance. Can be formulated for low temperature applications. Excellent for oil field service Usually not recommended in applications with concentrated acids or alkalis. Very high cost. Maximum continuous operating temperature is about 350°F.Styrene Butadiene(SBR):

Originally developed as a low cost substitute for natural rubber. Good water resistance and abrasion resistance Poor weathering resistance, but can overcome with specific raw material. Not recommended for contact with oils and solvents Not used with concentrated acids or alkalis. Maximum continuous operating temperature is about 225°F.BUTYL:

Very good resistance to most gases including air highly resistant to ozone and weathering. Abrasion resistance close to natural rubber and good for concentrated acids and alkalis. Not recommended for petroleum product exposure. Maximum continuous operating temperature is about 300°F.EPDM:

Exceptional resistance to weathering and ozone Excellent resistance to water, most gases, steam, and heat aging. Good for exposure to concentrated acids and alkalies, but not recommended for exposure to oils and solvents. Maximum continuous operating temperature is about 350°F.Viton:

High cost, but high performance material Outstanding resistance to most chemicals, oils and solvents. Good oxidation and ozone resistance. Maximum continuous operating temperature is about 650°F. "Viton" is a trademark of DuPont and signifies material produced by DuPont.